Simple, Safe, and Cost Effective Wastewater Management

Simple: The W.E. Inc. systems unique, patented, one step powder treatment is the heart of the technology. With this system, our machinery, your waste effluent, and our one step powder is all that is required. There is no need for highly paid technical personnel. There is no need for an array of different, often hazardous, chemicals. There is no need for laboratory supplies and equipment. If excess oils or solids are present, pre-treatment may be necessary, however, this is usually handled automatically, and with non-hazardous chemistry.

Safe: Unlike traditional wastewater treatment chemicals ( acids, harsh caustics, etc.), the W.E. Inc. range of powders and liquids are non-hazardous, are safe for workers, and require no special storage or handling.(See SDS for details).

Cost Effective: Cost per gallon to treat is typically less than 1/3 the cost per gallon for haul away. Return On Investment (ROI) for capital equipment is usually within only a few months. Additional savings may be realized when the treated fluids are recycled, since our technology can leave costly soaps, rust inhibitors, and other chemicals in the water. The bottom line is: a reduction in wastewater handling costs equals increased profit for your business.

Product Highlights:

- Fully Automatic packages available

- Many labor saving features and options

- Requires only 10 minutes of attendant labor per batch

- No hazardous by-products

- Guaranteed to meet discharge limits to local sewer

- Sludge is guaranteed to pass TCLP

- Low maintenance, available 3 year, 100% parts replacement warranty

- Handles most aqueous based fluid

All units feature:

- HD Steel Construction

- Designed to be operated by custodial personnel

- Allen Bradley Controls

- Push button auto fill function

- Auto indexing filter bed

- Rinse down package

- Float activated discharge pump

- Final stage canister fill

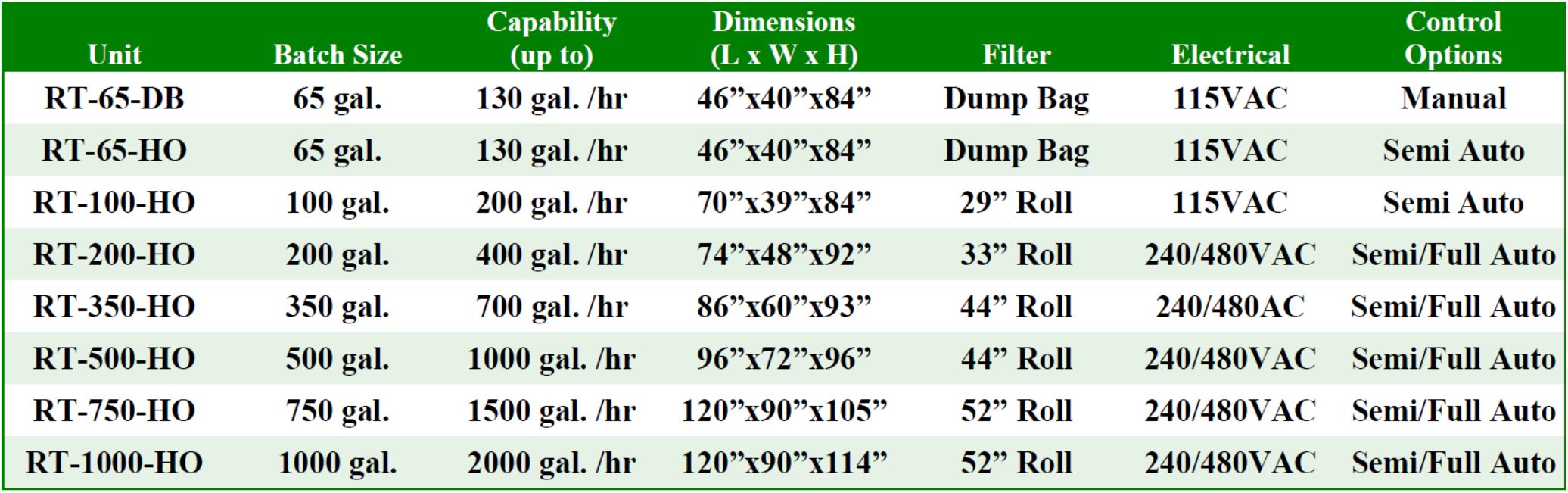

These units are semi-automatic batch treatment machines, capable of running 2 batches per hour. The RT-100 HO is a 100 gallon unit, the RT-350-HO is a 350 gallon unit and so forth.

This series consist of the following units:

RT-100-HO through RT-1000-HO:

- Designed for the low volume generator, these units feature a pull out cart and filter.

- The base model includes an on/off switch and an on-board, float-activated discharge pump – for transferring treated fluids to sewer or recycle vessel. No special skills are required to operate. A full cycle requires about (15) minutes of attendance.

- HO model comes equipped with an electrical control panel, an on-board auto sump pump. An auto fill function: simply push “fill start” button and the on-board pump will draw fluids from storage source into the mix tank. Other features include a rinse down package, countdown mixer timer and a final stage canister filter. A cycle requires only (5) minutes of attendance.

- Both models utilize a reusable filter bag that can handle from 2 to 5 batches of sludge before emptying is required.

- 3-year, 100% parts replacement warranty

RT-100-HO through RT-1000-HO:

- All HO models are semi-automatic and engineered to be operated by custodial personnel.

- Operator simply pushes “fill start” on the control panel to activate the “auto fill” function. An onboard pump will draw fluids from storage vessel and continue to transfer effluent until ‘full’ capacity is reached. A float sensor will deactivate the transfer pump, and illuminate a “RT Full” light on the control panel.

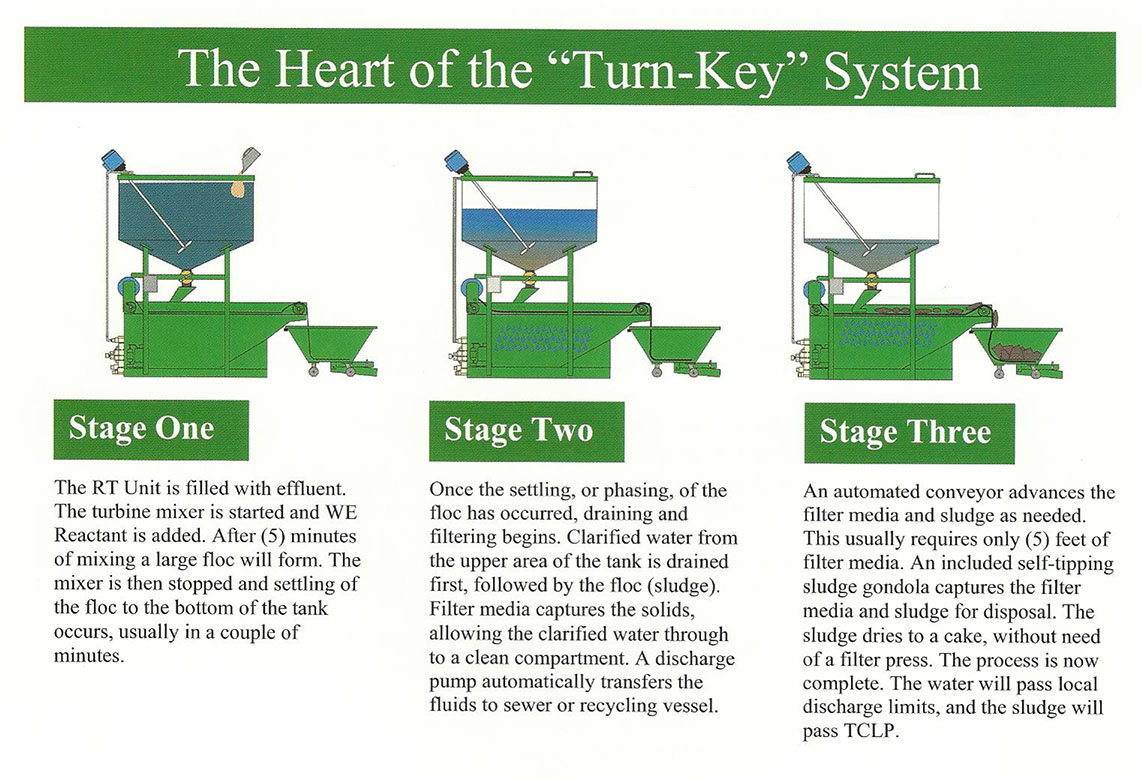

- Operator then sets the countdown mixer timer, adds Reactant and allows (5) minutes for a reaction to occur, e.g. separation of contaminants from water.

- Operator will allow (1) minute for settling, then open the drain/filter valves.

- The entire process limits operator attendance to approximately (10) minutes per batch – regardless of the model size.

- Other features include electrical control panel, rinsing package, auto-indexing filter bed, selftipping sludge gondola, final stage canister filter, and an on-board discharge pump for clarified liquid.

- Further options include fully automatic package (totally operator free), choice of 240 or 480VAC, choice of many more labor saving/convenience features. Please talk to your WE, Inc. Salesperson for details.

- The most noteworthy feature of all RT units and accompanying systems components is our 3-year, 100% parts replacement warranty!